Top Tips for Choosing the Best Work Bench on Wheels for Your Workshop

In the ever-evolving world of workshop equipment, the "work bench on wheels" has emerged as an essential tool for both amateur hobbyists and professional craftsmen. As highlighted by industry expert John Smith, “A well-chosen work bench on wheels can transform your workspace, making it not only more efficient but also more enjoyable.” This statement underlines the importance of selecting the right work bench tailored to your specific needs and workspace constraints.

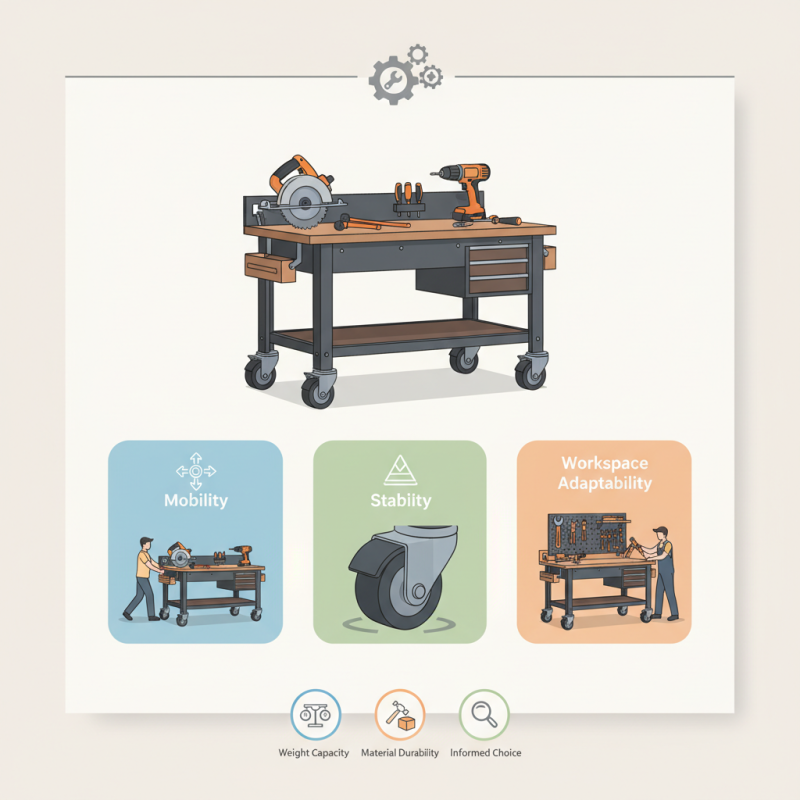

When choosing a work bench on wheels, one must consider various factors such as mobility, stability, and workspace adaptability. The design of these benches allows for easy maneuverability, which is crucial for maximizing productivity in a workshop setting. Whether you need to shift your bench for different projects or to clear space, a mobile work bench streamlines your workflow, making it an asset that contributes to a more organized and functional environment.

As we delve deeper into the process of selecting the perfect work bench on wheels, it's vital to understand the key features to look for and the common pitfalls to avoid. From weight capacity to material durability, making an informed choice will ensure that your investment serves you well for years to come.

Key Features to Consider for Work Benches on Wheels

When selecting a workbench on wheels for your workshop, several key features should be considered to ensure it meets your needs effectively. First and foremost, assess the weight capacity of the bench. Depending on your projects, you may require a sturdy surface that can support heavy materials and tools. Look for benches constructed from durable materials, such as solid wood or reinforced steel, which provide stability and longevity.

Another essential feature is the size and surface area of the workbench. A larger surface allows for more workspace, facilitating the accommodation of bigger projects and multiple tools simultaneously. Additionally, consider the height of the bench, ensuring it aligns with your comfort for prolonged use. An adjustable height option can be beneficial for various tasks and user preferences. Lastly, check the rolling mechanism of the wheels. High-quality wheels should provide smooth movement and stability when stationary, which is critical for safety during use. A locking system is also a valuable addition, preventing the bench from moving unexpectedly while you work.

Importance of Material Durability in Workshop Benches

When selecting a workbench on wheels for your workshop, one of the most critical factors to consider is the durability of the materials used in its construction. A robust workbench often consists of high-quality steel, hardwood, or a combination of both, which can withstand the rigors of heavy use. According to the Occupational Safety and Health Administration (OSHA), work-related injuries sustained from inadequate equipment can be significantly reduced by ensuring that workplace furniture is built from durable materials. This emphasizes the necessity for workshops to invest in benches that do not only meet immediate needs but can also endure frequent wear and tear.

Moreover, durability in workshop benches translates into long-term cost savings. A report by the American Society of Home Inspectors indicates that workbench maintenance significantly decreases when high-quality materials are utilized, leading to fewer replacements and repairs. For instance, steel-framed benches can endure up to 1,500 pounds of weight, which is crucial for professionals who deal with heavy machinery or tools. The longevity of these products means less frequent purchases, thus optimizing financial resources while ensuring a safe and efficient working environment. Choosing a workbench that prioritizes material durability is not just a wise decision for functionality but also an investment in workplace safety and productivity.

Material Durability Comparison for Work Benches on Wheels

Ideal Height and Size Specifications for Comfort and Efficiency

When selecting a workbench on wheels for your workshop, the ideal height and size specifications play a critical role in ensuring comfort and efficiency during use. According to industry standards, a workbench height should typically range from 28 to 36 inches, catering to both sitting and standing tasks. A well-designed workbench promotes ergonomic posture, significantly reducing the risk of repetitive strain injuries. In fact, studies from the Occupational Safety and Health Administration (OSHA) suggest that improving workstation ergonomics can lead to a 20-25% reduction in work-related musculoskeletal disorders.

Furthermore, the size of the workbench is equally important. A standard workbench depth of 24 to 30 inches offers ample surface area for various tasks, while a length of 48 to 72 inches is ideal for accommodating larger projects without sacrificing mobility. The American National Standards Institute (ANSI) states that sufficient workspace promotes productivity; therefore, a well-sized workbench not only supports your workflow but also enhances efficiency by minimizing clutter. Adapting to personal preferences, these specifications can result in an optimized workspace that caters to your specific project needs.

Mobility and Locking Mechanisms: Ensuring Stability and Safety

When selecting a workbench on wheels, mobility is a key factor that enhances the functionality of your workshop. A well-designed workbench should glide effortlessly across various surfaces, allowing you to reposition it as needed without strain. Look for models with sturdy casters that can pivot smoothly, enabling you to navigate tight spaces with ease. Additionally, consider the weight capacity; a heavier bench will require robust wheels to ensure safe movement and prevent tipping during transit.

Locking mechanisms are equally crucial for stability and safety. A workbench that features reliable locking casters will prevent unwanted movement while you work, ensuring that tools and materials remain secure. When assessing locking mechanisms, evaluate how easily they can be engaged and disengaged. It’s important to have a system that features an intuitive locking mechanism to promote quick setups without compromising on safety. Test the locks before purchasing, and make sure they hold firm even under pressure.

A tip for choosing the right workbench on wheels is to consider your workspace layout. Ensure that the bench can be easily maneuvered to different parts of your workshop for convenience. Another suggestion is to check the construction material; a robust frame not only supports mobility but also contributes to overall durability. By focusing on these mobility and locking features, you can find a workbench that elevates your workshop's efficiency while maintaining safety.

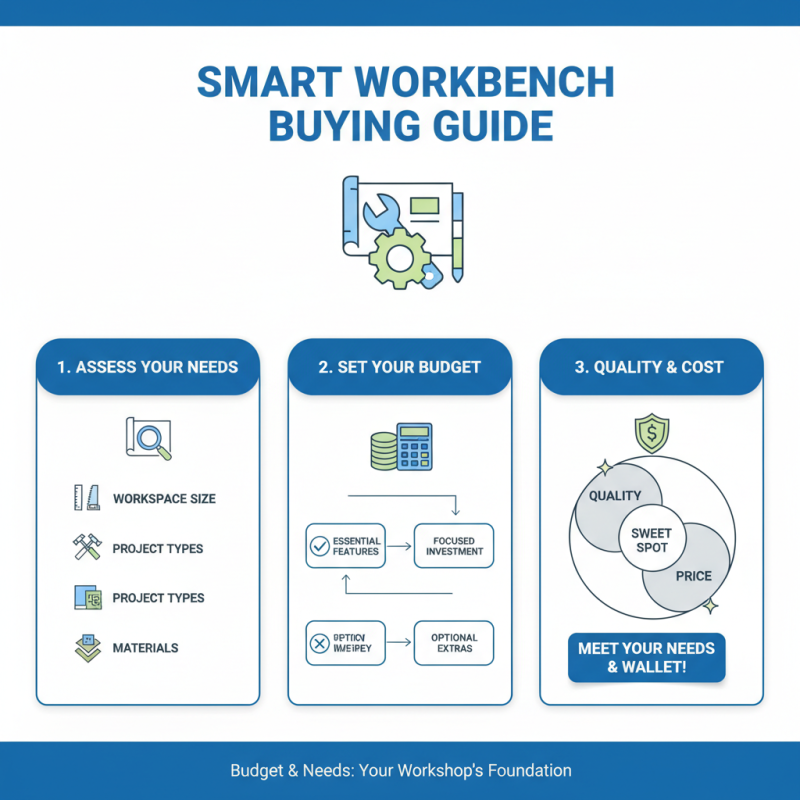

Budget Considerations: Balancing Quality and Affordability in Workshop Equipment

When selecting a work bench on wheels for your workshop, budget considerations play a crucial role in ensuring that you obtain a product that meets both your financial constraints and your quality requirements. It's essential to assess your specific needs before setting a budget. Consider the size of your workspace, the types of projects you'll undertake, and the materials you'll be working with. This understanding will help you differentiate between essential features and optional extras, allowing for a more focused investment.

Quality is paramount when it comes to workshop equipment, but it doesn't have to break the bank. Invest in materials that provide durability and stability, as these will enhance your workbench's longevity and functionality. Look for features like adjustable height, sturdy wheels, and ample workspace to ensure you are getting value for your money. Don't hesitate to explore various suppliers and compare their offerings. While it may be tempting to choose the cheapest option, remember that a little extra investment can lead to superior performance and longevity, ultimately saving you money in the long run.

Related Posts

-

How to Choose the Perfect Work Bench on Wheels for Your Workspace Needs

-

Top Strategies for Maximizing Efficiency with Work Bench on Wheels

-

How to Choose the Best Rolling Workbench for Your Workshop Needs

-

14 Best Rolling Work Benches for Ultimate Workspace Efficiency

-

Innovative Solutions for Efficient Rolling Work Table Procurement

-

7 Compelling Reasons Why the Best Work Bench on Wheels Revolutionizes Your Workspace Efficiency

Footer

Resource Center

Contact Us

1901 West Main Street

Washington, MO 63090

Main Directory: 1-800-227-4873

Email: sale@pangcofurniture.com

Affiliations