Exploring the Versatility of Best Work Bench Tool Boxes for Every Professional Need

In today's fast-paced professional environment, the versatility of the work bench tool box has become a crucial asset across various industries. According to a recent report by IBISWorld, the tool storage market is projected to grow by 4.5% annually, driven by the increasing demand for efficient workspace organization and improved productivity. From construction sites to repair workshops, these tool boxes are designed to meet diverse professional needs, offering customizable storage solutions that accommodate a range of tools and equipment.

Notably, the work bench tool box not only complements the functionality of work areas but also enhances safety and efficiency, as noted by the Occupational Safety and Health Administration (OSHA), which emphasizes the importance of organized workspaces in reducing accidents. As we explore the applications and benefits of these indispensable tools, it becomes evident why they are considered a must-have for professionals across different fields.

The Importance of Quality Tool Boxes in Enhancing Workbench Efficiency

When it comes to maximizing workbench efficiency, the importance of quality tool boxes cannot be overstated. A well-structured tool box provides organized storage that keeps tools easily accessible. This organization allows professionals to spend less time searching for the right tools and more time focusing on their tasks. A high-quality tool box can also withstand the rigors of daily use, offering durability and protection for valuable tools, which is essential in maintaining their longevity and performance.

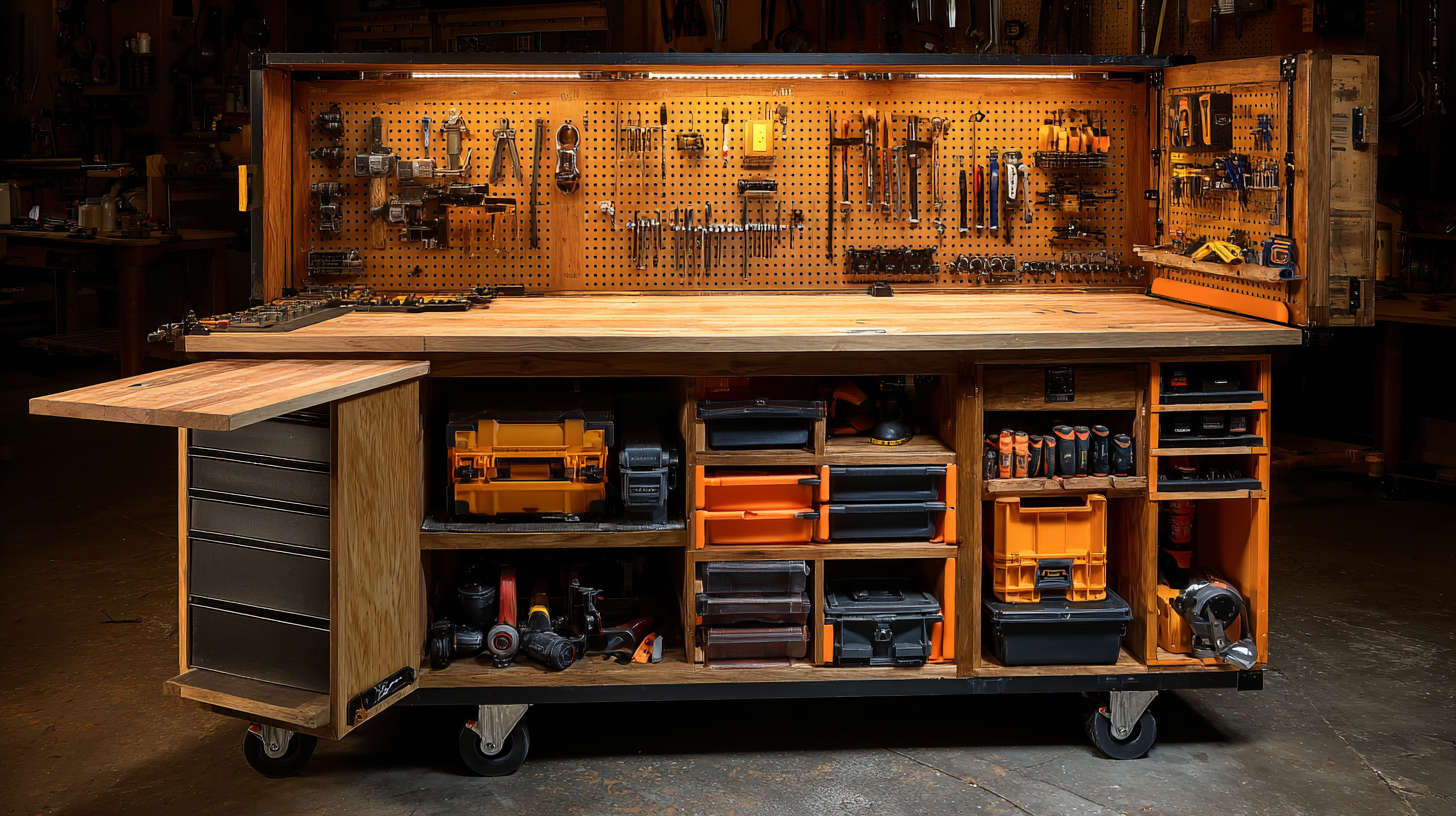

Moreover, a versatile tool box accommodates a range of tools, catering to various professional needs. Whether it’s for carpentry, electrical work, or automotive repair, the right tool box can be tailored to suit specific requirements. Features such as adjustable compartments, secure locking systems, and portable designs enhance functionality. By investing in a quality tool box, professionals not only ensure they have the right tools at hand but also create a more efficient and productive work environment. This strategic organization and accessibility ultimately lead to a smoother workflow and better outcomes in any project.

Key Features to Look for in a Professional Tool Box: Durability and Functionality

When selecting a professional tool box, two critical features stand out: durability and functionality. According to a market analysis by Industry Research, the global tool box market is anticipated to reach $15 billion by 2025, driven largely by the increasing demand from construction and manufacturing sectors. Professionals require tool boxes that can withstand harsh environments while providing easy access to their tools. Materials like heavy-duty steel and high-impact plastics not only enhance durability but also ensure that the investment is long-lasting.

Functionality goes beyond mere storage; it involves the proper organization of tools for maximum efficiency. A study from Freedonia Group reveals that tool boxes with modular designs can increase productivity by up to 25%. Features such as adjustable compartments, integrated tool trays, and robust locking mechanisms enable professionals to customize their tool storage, making essential tools readily accessible. When selecting a tool box, understanding these critical attributes can significantly enhance a professional's workflow and protect their critical instruments against wear and tear in demanding work environments.

Industry Trends: The Rise of Modular Tool Box Systems for Professionals

The rise of modular tool box systems has revolutionized the way professionals approach organization and efficiency in their workspaces. A recent study by Grand View Research indicates that the global tool storage market is projected to reach $14.3 billion by 2028, expanding at a CAGR of 4.5%. This growth is largely attributed to the increasing demand for customizable solutions that cater to diverse professional needs. Modular tool boxes allow users to adapt and expand their storage solutions to fit projects ranging from automotive repair to construction, thereby enhancing workflow and productivity.

Moreover, the emphasis on mobility in professional tool storage cannot be overstated. According to a survey conducted by the American Institute of Architects, over 70% of professionals cite ease of transport as a key factor when choosing their tool storage. Modular systems not only provide individuals with the flexibility to customize their setups, but they also facilitate easier transportation between job sites. This trend is particularly significant in industries where time is of the essence and the ability to access tools quickly can make a dramatic difference in project timelines and overall efficiency. As more professionals recognize the benefits of these innovative storage solutions, the adoption of modular tool box systems is expected to continue its upward trajectory.

Sourcing Quality Suppliers: How to Evaluate and Select the Right Manufacturer

When sourcing quality suppliers for workbench tool boxes, understanding how to evaluate and select the right manufacturer is key to ensuring you receive durable and reliable products. Start by researching potential suppliers thoroughly; investigate their reputation within the industry, customer reviews, and their history in manufacturing. A solid track record in producing quality tools will give you confidence in their capabilities.

**Tip:** Always request samples before committing to a bulk order. This gives you the opportunity to assess the quality of workmanship and materials firsthand.

Additionally, consider the manufacturer’s production capabilities and certifications. This information can be critical, particularly if you require specific materials or compliance with certain industry standards. Establishing a clear line of communication with potential suppliers can help you gauge their responsiveness and willingness to meet your needs.

**Tip:** Prepare a list of questions addressing your specifications and manufacturing processes to ensure that the supplier can meet your requirements effectively.

Exploring the Versatility of Best Work Bench Tool Boxes

This chart illustrates the different types of workbench tool boxes preferred by professionals in various fields. Each bar represents the percentage of usage among carpenters, mechanics, electricians, and plumbers.

Cost-Benefit Analysis: Investing in High-Quality Tool Boxes for Long-Term Impact

Investing in high-quality tool boxes is not merely a purchase; it is a strategic decision that can yield significant long-term benefits for professionals across various industries. According to a survey from the National Hardware Show, 70% of contractors reported that well-organized and durable tool storage significantly enhances their productivity. This is particularly crucial in fields where time and efficiency directly impact profitability. A reliable tool box can streamline workflow, allowing professionals to spend less time searching for tools and more time on actual work.

Moreover, the cost-benefit analysis of investing in premium work bench tool boxes reveals that, while the initial expenditure may be higher, the durability and longevity of these products often result in lower overall costs. A report by the American Supply Association indicates that high-quality tool boxes can last up to 15 years, compared to just 5 years for cheaper alternatives. This translates into less frequent replacements and minimal downtime. As industries evolve and the demand for efficiency increases, professionals must consider tool storage solutions not just as an accessory, but as an essential component of their operational strategy.

Exploring the Versatility of Best Work Bench Tool Boxes for Every Professional Need

| Tool Box Type | Material | Dimensions (inches) | Price ($) | Durability (Years) | Storage Capacity (lbs) | Features |

|---|---|---|---|---|---|---|

| Portable Tool Box | Plastic | 18 x 12 x 8 | 49.99 | 5 | 30 | Water-resistant, Carry handle |

| Heavy-Duty Tool Chest | Steel | 40 x 18 x 25 | 249.99 | 15 | 500 | Lockable, Drawers |

| Rolling Tool Box | Aluminum | 22 x 14 x 12 | 159.99 | 10 | 200 | Telescoping handle, Spinner wheels |

| Multi-Drawer Tool Organizer | Plastic | 24 x 12 x 36 | 89.99 | 7 | 150 | Multiple compartments, Stackable |

Footer

Resource Center

Contact Us

1901 West Main Street

Washington, MO 63090

Main Directory: 1-800-227-4873

Email: sale@pangcofurniture.com

Affiliations